We measure and analyze your pump and water systems.Determines your needs and possible We are preparing feasibility reports for your productivity project applications.

Measurement services :

In pump systems, instant conditions are usually neglected.You need to choose the right system at the same time You must monitor the productivity values of your system continuously or at least in certain periods. We collect values with our expert measurement tools and determine instant efficiency conditions.Any If there is any problem, we recommend the best solutions for you if there is any problem.

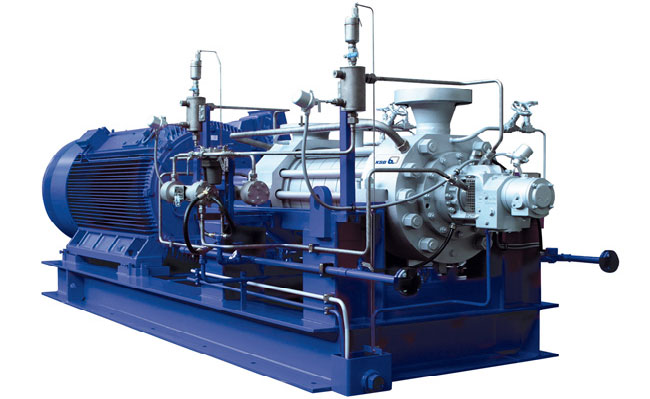

According to the measurement results, we provide feasibility reports for all system updates.Required updates We offer turnkey solutions.Pump and engines of water wells, rakors, valves or pipe connections can be changed.Our solutions are electrical and electronic control devices equipment and communication systems contains.These solutions are compatible with the metirius devices and advanced cloud software solutions with advanced cloud device contains.We can produce solutions for water wells, water tanks, promotion stations and pipelines.Municipalities, irrigation Cooperatives, industrial facilities and farmers constitute our working areas.

We supply high efficiency fixed magnets for your water wells.The rotors of these engines are neodymium magnets has.PM motors are completely different from classic engines with squirrel cage rotors.From the stator of the rotor of the PM motor It does not require magnetic flux passage.In this way, there will be no magnetic transmission losses in PM motors and 10 kW submersible pumps You can even get more than 90 %yield value.High yield also reaches low temperature analysis.This The motors operate at approximately ambient water temperature.Less probability of burning for these fixed water pumping processes means.Requires less drying effect.PM motors cannot be operated without special AC drives.All Metirius Well EX models support PM motor options.Your investments pay themselves faster with PM motors.

Today, the common problem of many public institutions and private enterprises are high electricity bills.With the energy efficiency projects it has made, our company offers the ease of payment in the projects as well as to zero.In addition to motopomp revision and system automation in water and sewage administrations, the institution provides great savings from water to water thanks to the projects we have drawn for loss leaks.In special industrial enterprises, we intervene in the transfer of the engine in the projects we make with AG and OG drivers and maximum savings are provided in addition to better process control.

We encounter many problems caused by incorrect projects in the promotion centers.For example, the wrong motopomp selection is not only shortened and uninterruptedly operational of engines, but also causes energy consumption.Thanks to the precision measurements in the promotion center projects made by our company, the motors are controlled by the driver according to the warehouse level where the promotion center has been poured.Thus, the engines should be used equally and the cost of operating from failures will disappear.In addition, extra savings are provided thanks to the automation system, which will allow the motors to work less during the hours when the energy is expensive (points)..

Waste water should be transmitted to the treatment plants for reuse.The correct transmission of this water causes unwanted problems to occur.Technological promotion management systems provide solutions to the intelligent transmission of waste water.We closely examine the problems in waste water transmission facilities and offer solutions.We install waste water transmission stations at least in need of service and maintenance and develop management systems for the long -lasting use of the promotion station.

Water collected from underground and above ground sources is sent to water tanks.Thanks to our warehouse monitoring systems, the pumps that feed the tank can work automatically.Thus, we can keep the warehouse water level under constant control.The chlorine dosing process is performed for drinking and use of water in the warehouse.It also makes the pH, blur, conductivity and chlorine measurements of water.

There is a pressure change in the network due to the difference in jeans and the multi -branching of user points.High pressure damages the water line and causes loss of water.Press control systems are installed at the specified points by measurements to reduce the pressure.The operation of the system is checked by putting tracking systems at the last point where the water goes.The water is sent to the user in the most healthy and efficient way.

The first step of the journey of the water we use is to remove it.After the water wells are opened, the water is delivered to the user efficiently.Water measurements are made for efficiency and the correct pump is selected.Metirius control device and the changes in the water in the well during the year to work in the most efficient way to work.

Water pumps are used in many industrial enterprises.Some projects we do productivity projects;

In water cooling towers, functioning is on the circulation of water.Pumps are also used to move water from one place to another.In the system, deaths are made and the most appropriate pump is selected and installed.According to the operation of the system, control software is made in the most efficient way.

The boiler fattening pumps used in industrial enterprises are high -cost pumps.Therefore, these pumps used in enterprises are expected to work stable with more periodic maintenance.If these pumps work at high pressure and temperature are selected correctly, both operating costs will decrease and postures for maintenance will decrease.In this field, we come and analyze with our expert engineer team and renew your systems according to the need.Thanks to our automation system, we run your pumps in the most efficient way and carry out turnkey works.

The task of the circulation pumps is to deliver the heated or cool installation water to the heat distribution points sufficiently.Due to incorrect projects, institutions and private companies often have to encounter faults and renew the systems.Thanks to our frequency converter systems, we carry out projects that will provide optimum work on circulation pumps.